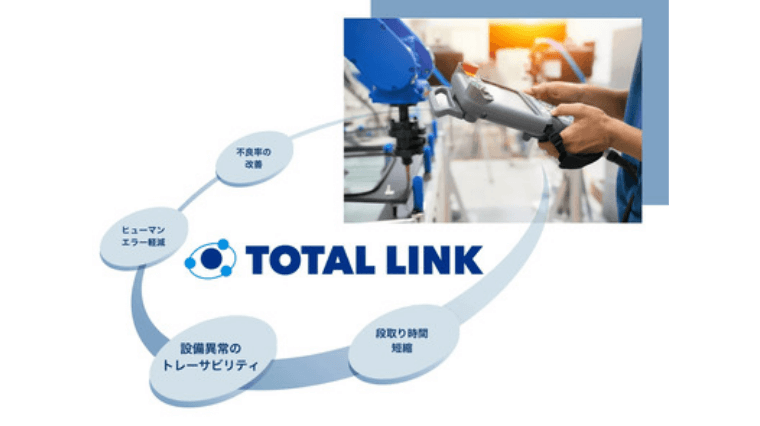

- Total Link

Batch management of settings, startup, and monitoring of peripheral equipment. Automation, "quality improvement," and "cost reduction" of injection molding will be realized.

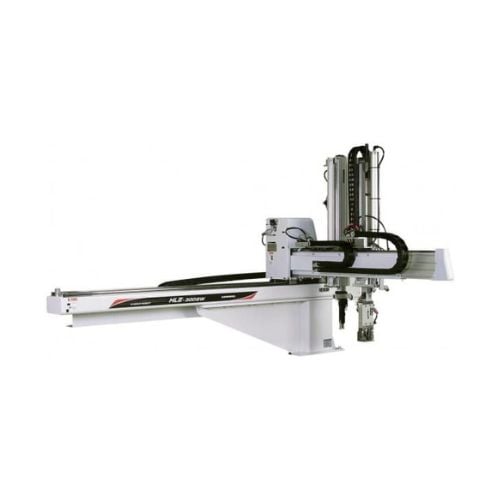

- Take-out Robot

Productivity is improved by reducing take-out time. HARMO's take-out robot contributes to solving problems at molding sites, such as manpower shortages.

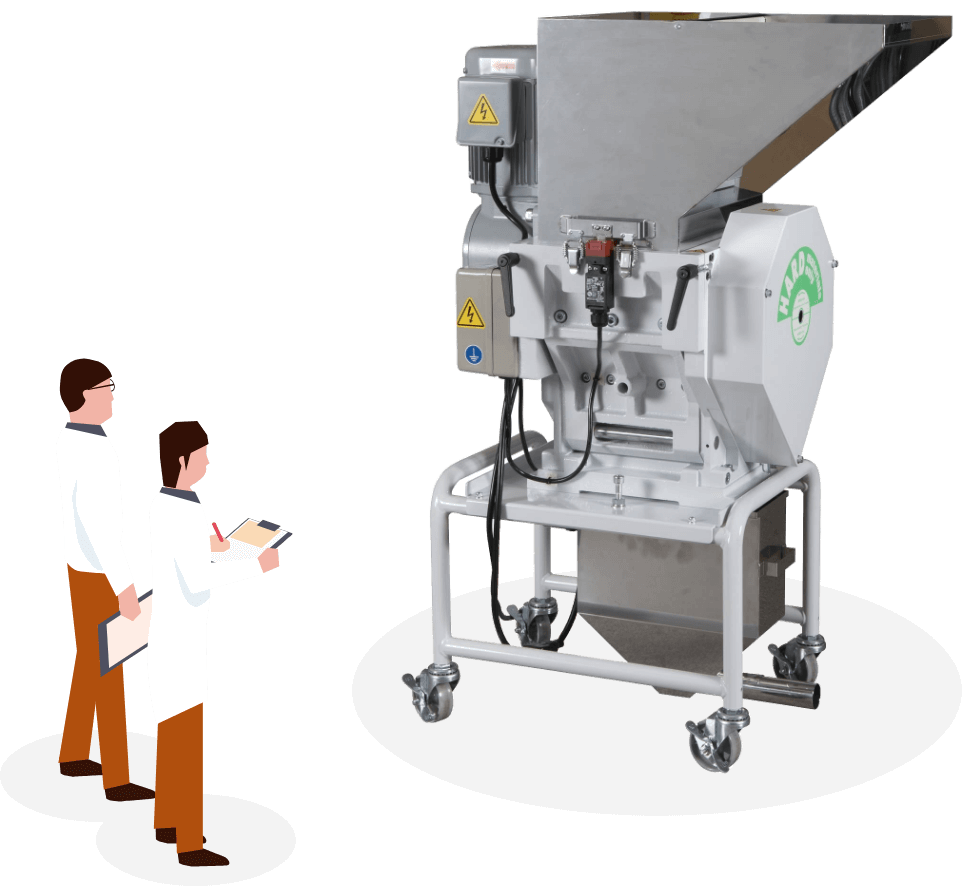

- Peripheral Equipment

We have a full range of products such as Gran Cutter, Stock System, Packing Machine, Dryer, etc. We solve problems at molding sites with a product lineup that only a comprehensive manufacturer of peripheral equipment in Japan can offer.

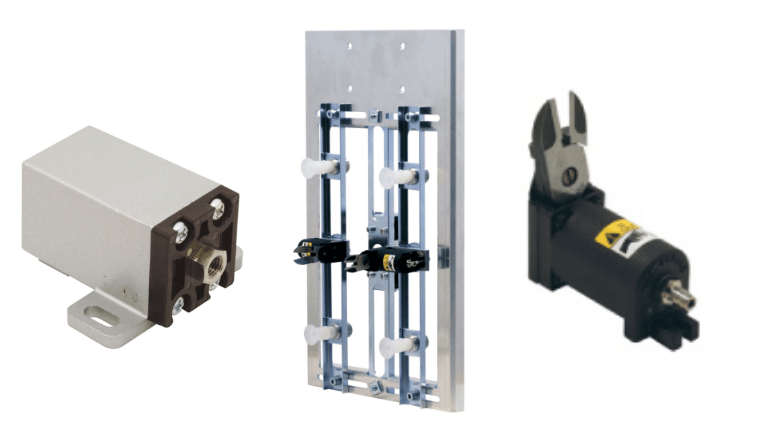

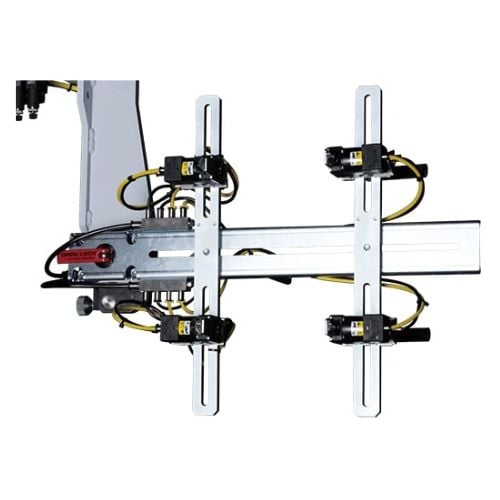

- Attachment of EOAT

A wide variety of holders, mini-cylinders, air nippers, and vacuum pads are lined up. We make the molding site easy to work in and efficient.

Resin sample cutting

Sample cutting is available

It is also possible to check your runner, etc. for sample cutting.

In this case, please prepare about 30 shots of the runner.

+81 265-73-3699

(except Saturday, Sunday, national holidays and our company holidays)

Online Exhibition / Seminar

Tips of peripheral equipment and process improvements for injection molding

Webinar

【For Thailand】HARMO's Webinar|Realize the productivity improvement by shortening take-out time with 2-axis servo driven swing robot

We prepared the suggestions for the people who have problems such as Productivity improvement, Less operation at mold changing, and Ensure the worker's safety.

Webinar report

【For Thailand】HARMO's webinar report|Realize the productivity improvement by shortening take-out time with 2-axis servo driven swing robot

【For Indonesia】HARMO's webinar report|Reduce material cost with Gran cutter

【For Vietnam】HARMO's webinar report|Reduce material cost with Gran cutter

HARMO Channel

.jpg?width=500&height=500&name=%E8%B6%85%E5%A4%A7%E5%9E%8B%E4%BB%95%E6%A7%98%7C%E3%82%A2%E3%82%A4%E3%82%B3%E3%83%B3%20(1).jpg)

%E3%83%9A%E3%83%BC%E3%82%B8%7C%E3%82%A2%E3%82%A4%E3%82%B3%E3%83%B3.jpg?width=500&height=500&name=_%E3%83%9B%E3%83%AB%E3%83%80%E3%83%BC(%E4%BD%9C%E8%A3%BD%E4%BE%8B)%E3%83%9A%E3%83%BC%E3%82%B8%7C%E3%82%A2%E3%82%A4%E3%82%B3%E3%83%B3.jpg)

.jpg?width=500&height=500&name=%E5%90%B8%E7%9D%80%E3%83%91%E3%83%83%E3%83%88%E3%81%AE%E3%82%A2%E3%82%A4%E3%82%B3%E3%83%B3%7C%E6%A0%AA%E5%BC%8F%E4%BC%9A%E7%A4%BE%E3%83%8F%E3%83%BC%E3%83%A2%20(1).jpg)

%7C%E6%A0%AA%E5%BC%8F%E4%BC%9A%E7%A4%BE%E3%83%8F%E3%83%BC%E3%83%A2.jpg?width=500&height=500&name=%E3%83%AF%E3%83%B3%E3%82%BF%E3%83%83%E3%83%81%E3%82%A2%E3%82%BF%E3%83%83%E3%83%81%E3%83%A1%E3%83%B3%E3%83%88%7C%E3%83%9B%E3%83%AB%E3%83%80%E3%83%BC%20(%E5%8F%96%E5%87%BA%E6%A9%9F%E5%81%B4)%7C%E6%A0%AA%E5%BC%8F%E4%BC%9A%E7%A4%BE%E3%83%8F%E3%83%BC%E3%83%A2.jpg)

%7C%E6%A0%AA%E5%BC%8F%E4%BC%9A%E7%A4%BE%E3%83%8F%E3%83%BC%E3%83%A2.jpg?width=500&height=500&name=HC15BPX%7C%E3%83%AC%E3%83%90%E3%83%BC%E3%83%81%E3%83%A3%E3%83%83%E3%82%AF(%E3%83%95%E3%82%A3%E3%83%B3%E3%82%AC%E3%83%BC%E3%83%84%E3%83%BC%E3%83%AB%E4%BB%98)%7C%E6%A0%AA%E5%BC%8F%E4%BC%9A%E7%A4%BE%E3%83%8F%E3%83%BC%E3%83%A2.jpg)