What Total link can do is to set, activate and monitor the periphereal equipment at once.

Harmo's Total link

Online exhibition / Webinar

【For Thailand】HARMO's Webinar|Realize the productivity improvement by shortening take-out time with 2-axis servo driven swing robot

We prepared the suggestions for the people who have problems such as Productivity improvement, Less operation at mold changing, and Ensure the worker's safety.

【For Thailand】HARMO's webinar report|Realize the productivity improvement by shortening take-out time with 2-axis servo driven swing robot

【For Indonesia】HARMO's webinar report|Reduce material cost with Gran cutter

【For Vietnam】HARMO's webinar report|Reduce material cost with Gran cutter

Product

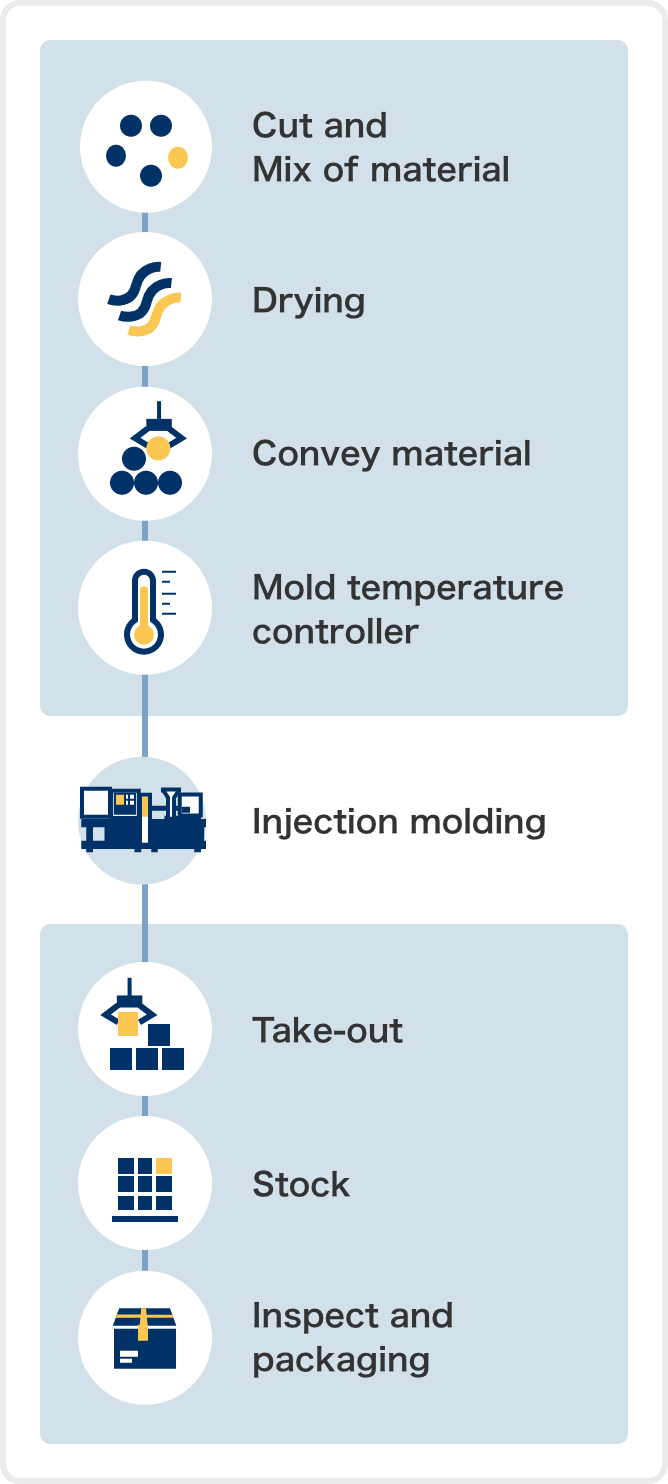

Realize automation, quality improvement and cost reduction of injection molding by setting, activating and monitoring peripheral equipment at once

To enable a 24 hour and stable operation uninfluenced by worker productivity.

Productivity improvement by reducing the mold changing time and take-out time.

Decrease defect rate of products.

To reduce material cost by improving recycling rate of sprue/runner.

Technical information of Injection molding

【For Indonesia】Cara mempersingkat 30% waktu dalam proses pengambilan sprue dengan menggunakan robot swing yang digerakan oleh servo

%20(1).png)

【For Indonesia】Tidak perlu penyesuaian gerakan (take-out robot)

【For Indonesia】Berdasarkan siklus waktu 62% lebih pendek dibandingkan penggunaan robot dengan silinder udara, secara signifikan meningkatkan aktivitas produksi

%20(1).png)

【For Thailand】ไม่จำเป็นต้องปรับตั้งระยะ (หุ่นยนต์หยิบ/จับ)

Because Harmo is specialized in helping an automation of injection molding process

We can suggest the improvement

for the whole process of injection molding.