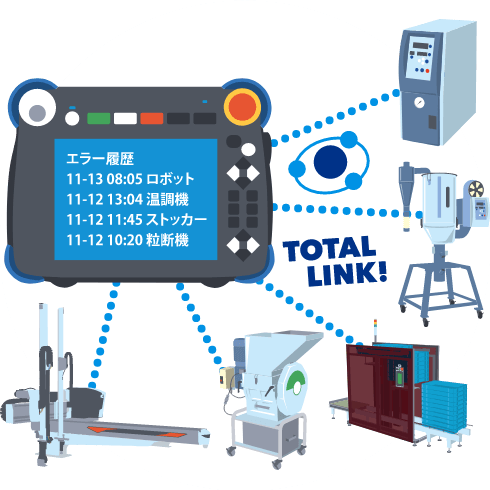

Manage the whole injection molding

process with Total link

Services

Realize automation, quality improvement and cost reduction of injection molding

by

setting,

activating and monitoring peripheral equipment at once

Reduce setup time

Activate, stop and setting of peripheral equipment at once with the controller of the robot.

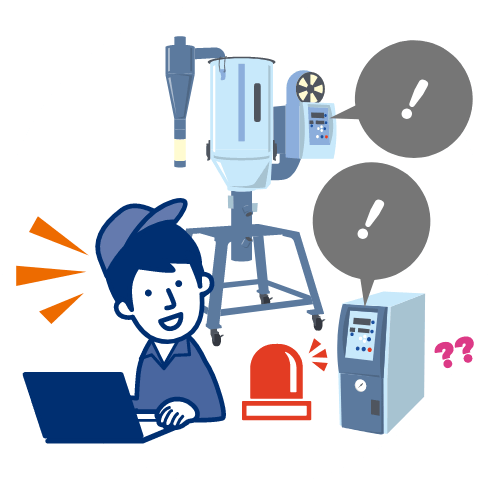

Reduce human error

The robot calculates the scheduled preparation start time automatically moreover the robot announces the wrong connection of equipment.

Cost reduction

The robot calculates the production end time and manage to supply only the material to the minimum.

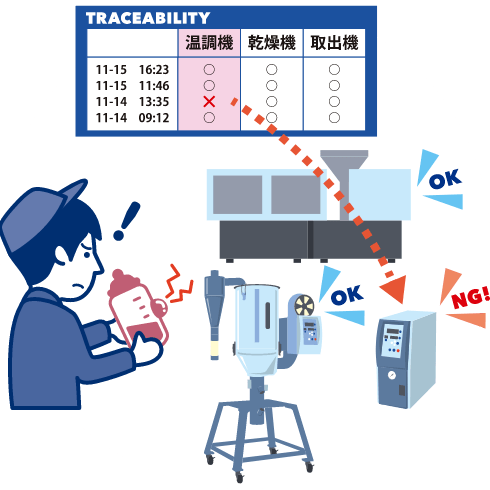

Traceability of

equipment abnormalities

You can check the error log and operational data of the robot and peripheral equipment.

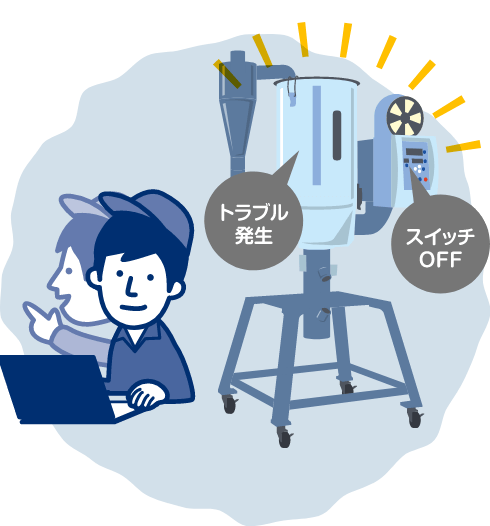

Reduce production defects

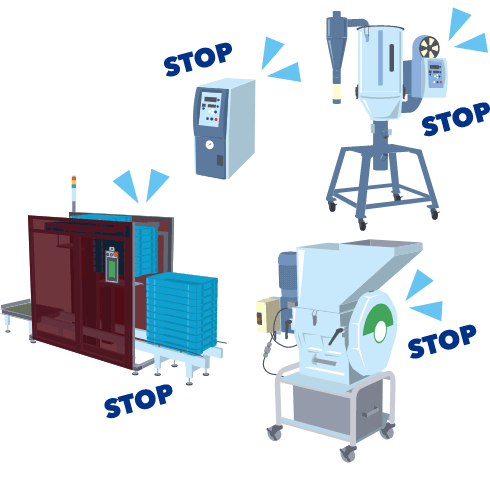

The robot monitors the abnormal of peripheral equipment and control them automatically.

Protect opportunity loss that the operator doesn't notice the setting mistake and stop of equipment.

Prevent opportunity loss of complaint with the delivered products.

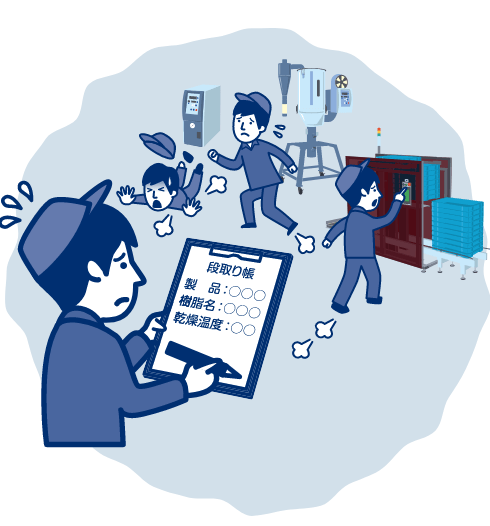

Protect opportunity loss of wasting the extra material when changing the material.

Changing the material

Protect

opportunity loss

of wasting

the

extra

material

when changing the material

$319 × 10 units × 12 months = $38,280 per a year

*1 [Production condition of remake (per a hour)] Quantity: 180 shots x 4 cavities / Sell price:

$0.14 / Wages: $55 / Machine processing cost: $28

*2 [Figuring out the cause] Wages for 1 person: $55 per an hour / 2 different shifts

*3 [Figuring out the cause] Working time: 24 hours (if it happens 1 time in 1 year)

Contact us if you

have problems of

automation,

quality improvement and cost reduction.

About Expenses

To those people who have problems or tasks

Motion

Advantages

POINT01

POINT02

POINT03

POINT04

Contact us if you

have problems of

automation,

quality improvement and cost reduction.

About us

We grasp the high-level and wide-ranging needs of the world standard and build trust with our customers through perfect after-sales service.

| Company name | HARMO Co., Ltd. |

|---|---|

| Business Activities | Development, manufacture and sales of industrial robots (automated pick-up equipment for injection molded parts) and streamlined auxiliary machines for plastic molding machine |

| Address | 4124-1 Minamiminowa-mura Kamiina-gun Nagano, Japan 399-4595 |

| Phone | +81-265-73-8820 |

| Sales Office (Subsidiary) |

Singapore, Philippines, Malaysia, Thailand, Vietnam, Indonesia, Shenzhen, Shanghai, America, Mexico |

| Factory | Suzhou |

Global Agency

Development, manufacture and sales of industrial robots (automated pick-up equipment for injection molded parts)

and streamlined auxiliary machines for plastic molding machine.