- Top

- Robot

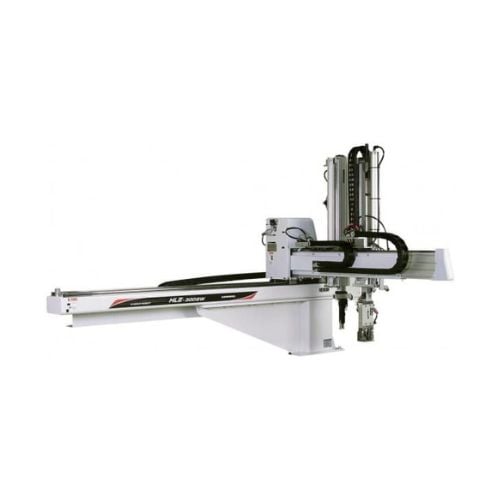

- ARXⅢ series (Global model)

- ARXⅢ-150/250S・G

Traverse type servo-driven take-out robot

Overseas specifications (Medium size)

ARXⅢ-150/250S・G

Medium size, 120 to 350 tons, 2-plate/3-plate

Overseas specifications

Traverse type servo-driven take-out robot

ARXⅢ-150/250S・G

- Overseas specifications

- Medium size

- 120 to 350 tons

- 2-plate/3-plate

| IMM size (ton) |

Maximum payload | Supported Plates (Molds) |

Feature 1 | |

|---|---|---|---|---|

| ARXⅢ-150S | 120〜250 | 5 | 2 | Medium size, overseas specifications |

| ARXⅢ-150G | 120〜250 | 5 | 3 | Medium size, overseas specifications |

| ARXⅢ-250S | 180〜350 | 5 | 2 | Medium size, overseas specifications |

| ARXⅢ-250G | 180〜350 | 5 | 3 | Medium size, overseas specifications |

Maximum payload

5kg(including attachments)

Product video

Controller

HRS-1200

Quick program

- Programs can be easily added on the controller screen at the customer's site.

- Programs can be created while the take-out robot is in operation.

Group management

- Group management of increasing mold data by customer and product.

Free palletizing

- Able to freely set the product release position to 256 points.

Production control functions

- Various settings such as "automatic operation OFF at the end of production" can be made by production monitor and production environment settings.

Languages switching

- 5 languages can be selected (Japanese, English, Chinese, Korean, and Thai)

- Other European languages can also be switched.

Linkage with peripheral equipment (optional)

Total Link

Peripheral equipment settings and monitors can be collectively managed. Contributes to shorter setup time.

- Batch automatic setting of peripheral equipment with robot mold data.

- Batch startup of all peripheral equipment by robot

- Batch monitoring of all peripheral equipment on the robot

Peripheral equipment communication (HAL-NET)

Interlocking with HARMO "F series peripheral equipment" is possible. Peripheral equipment can be operated from the operation screen of the take-out robot.

Solving problems at molding sites

Automation and manpower saving

Automatic gate cutting of molded products

HARMO's "Take-out robot x nipper device = automation" is useful to solve manpower shortage and realize 24-hour operation.

Case 1

A table type nipper manufacturer, which charges 3-5 million yen per unit, succeeded in dramatically reducing costs by using our servo wrist unit and wait nippers.

Case 2

A company that used to spend 400,000 yen per month for in-house workers to do gate cutting of 4 parts taken out by a swing-type robot from other company, realized automation by using HARMO's traverse running robot and waiting nippers. The entire cost of in-house work was reduced.

Product Specifications

| ARXⅢ-150S | ARXⅢ-150G | ARXⅢ-250S | ARXⅢ-250G | |

|---|---|---|---|---|

| Main vertical stroke (mm) | 800【900】【1000】 | 800【900】【1000】 | 1000 | 1000 |

| Sub vertical stroke (mm) | ー | 850【950】【1050】 | ー | 1050 |

| Main kick stroke(mm) | 678(122~800) | 610(190~800) | 678(107~785) | 610(175~785) |

| Sub kick stroke (mm) | ー | 610(45~655) | ー | 610(30~640) |

| Traverse stroke (mm) | 1400【1600】【1800】【2000】 | 1400【1600】【1800】【2000】 | 1600【1800】【2000】 | 1600【1800】【2000】 |

| Main home position (mm) | 150 | 150 | 250 | 250 |

| Maximum reach (mm) | 800 | 800 | 785 | 785 |

| Sub minimum reach (mm) | ー | 45 | ー | 30 |

| Wrist rotation(°) | 90 | 90 | 90 | 90 |

| Wrist unit torque (Nm) | 22.7 | 22.7 | 22.7 | 22.7 |

| Maximum payload (kg) | 5kg (including attachments) | 5kg (including attachments) | 5kg (including attachments) | 5kg (including attachments) |

| Weight (kg) | 218 | 237 | 251 | 261 |

| Width × Depth × Height (mm) | 2176×1500×1498 | 2176×1500×1511 | 2416×1500×1798 | 2416×1500×1811 |

| Working air pressure (MPa) | 0.5 | 0.5 | 0.5 | 0.5 |

| Air consumption (ℓ/cyc"ANR") | 1.15 | 1.17 | 1.15 | 1.17 |

| Control method | Digital AC servo motor | Digital AC servo motor | Digital AC servo motor | Digital AC servo motor |

| Power source (V) | 3-phase AC200V to 220V ± 10% (50Hz/60Hz) / Single-phase AC200V to 220V ± 5% (50Hz/60Hz) | 3-phase AC200V to 220V ± 10% (50Hz/60Hz) / Single-phase AC200V to 220V ± 5% (50Hz/60Hz) | 3-phase AC200V to 220V ± 10% (50Hz/60Hz) / Single-phase AC200V to 220V ± 5% (50Hz/60Hz) | 3-phase AC200V to 220V ± 10% (50Hz/60Hz) / Single-phase AC200V to 220V ± 5% (50Hz/60Hz) |

| Maximum power consumption (W) | 1000 | 1600 | 1000 | 1600 |

| Power equipment capacity(VA) | 3000 | 4000 | 3000 | 4000 |

| Maximum current consumption(A) | 8.50 | 11.50 | 8.50 | 11.50 |

| ARXⅢ-150S | ARXⅢ-150G | ARXⅢ-250S | ARXⅢ-250G |

【 】=Option

Standard Specifications

- Product grip

- Vacuum circuit

- Main sprue gripper

- Fine adjustment function in auto operation

- 500 mold memories

- Language switching function (5 languages)

- Horizontal wrist unit on mold

- Wrist rotation in the middle of travel

- Out mold home position

- 1ST ENTRY

- Molding defect discharge

- Initial reject release counter

- In-mold release

- Runner midway release

- Main operation switching

- Equal pitch palletizing

- Different pitch palletizing

- Multiple placement (4P)

- Above mold horizontal home posision

- Backward home posision/li>

- Quick key (timer, speed, I/O)

- I/O graph

- Servo monitor

- Confirmation operation

- Replacement position setting

- Password setting

- Log function

- Sampling

- Sampling counter

- Pass operation

- Quick Program (additional 256 steps, 64 points)

- Free palletize (256p)

- Sub arm independent control

- Automatic OFF at end of production

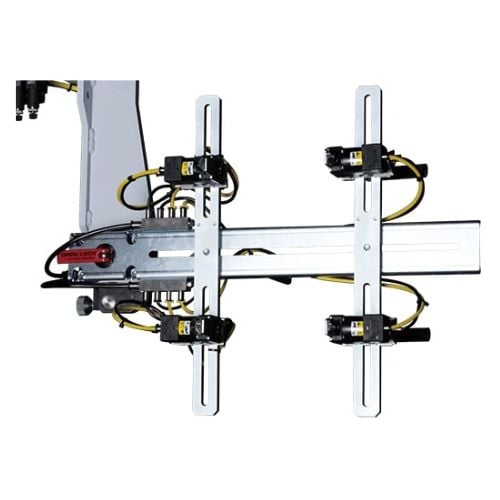

Option

- Product grip 2 units

- Product grip 4 units

- Vacuum circuit 2 units

- Vacuum circuit 4 units

- Vacuum & Blow

- Vacuum & Blow 2 units

- Vacuum & Blow 4 units

- TA nipper (without handle)

- Wait nipper slide valve

- Indicator lights (1 color / 3 colors)

- Traverse end pillar

- Pressure monitoring

- Specified color

- Air blow

- Conveyor signal

- Stocker signal

- Grip nipper

- Valve extension

- Gripper rotation mechanism

- HAL-NET (peripheral equipment communication)

- Simple one-touch gripper

New Information about this product

No articles found.

No articles found.

No articles found.

No articles found.

No articles found.

No articles found.

No articles found.

No articles found.

No articles found.

No articles found.

No articles found.

No articles found.

No articles found.

About us

Company name

HARMO Co., Ltd.

Business Activities

Development, manufacture and sales of industrial robots (automated pick-up equipment for injection molded parts) and streamlined auxiliary machines for plastic molding machine

Address

4124-1 Minamiminowa-mura Kamiina-gun Nagano, Japan 399-4595

Phone

+81-265-73-8820

International Marketing Department

- Address 4124-1 Minamiminowa-mura Kamiina-gun Nagano, 399-4595

- TEL : 0265-73-8820

- FAX : 0265-73-8964

- E-mail : kaigai@harmo-net.co.jp

- Sales Office (Subsidiary) Singapore, Malaysia, Thailand, Vietnam, Indonesia, Shenzhen, Shanghai, America

- Factory Suzhou

Sales Office (Subsidiary)

SINGAPORE

HARMO CO.,(SINGAPORE) PTE., LTD.

23TAGORE LANE #01-03 TAGORE 23 WAREHOUSE

SINGAPORE 787601

- TEL : +65-6481-1764

- FAX : +65-6481-6130

- E-mail : general@harmo.com.sg

INDONESIA

Festival Boulevard Blok AA 11 No61 Grand Wisata Desa Lambangsari Kec. Tambun-Selatan Kab. Bekasi 17510

- TEL : 021-8262-1667 / 68

- FAX : 021-8262-1726

- E-mail : hiro-tsuchiya@harmo-net.co.jp

MALAYSIA

HARMO CO., (MALAYSIA) SDN. BHD.

LOT 0034, KOMPLEKS SENTRAL No.33, JALAN SEGAMBUT

ATAS 51200 KUALA LUMPUR MALAYSIA

- TEL : +60-3-6251-2057

- E-mail : t_osaki@harmo-net.co.jp

Penang Office

HARMO CO., (MALAYSIA) SDN. BHD.

No.10, GROUND FLOOR JALAN PERAI JAYA 6, BANDAR BARU

PERAI JAYA, 13700 PERAI PENANG MALASIA

- TEL : +60-4-3972057

- E-mail : t_osaki@harmo-net.co.jp

THAILAND

HARMO (THAILAND) LTD.

410/71-72 SOI RATCHADAPISEK 24,RATCHADAPISEK RD., SAMSENNORK,HUAY-KWANG, BANGKOK 10310

- TEL : +66-2-541-4287

- FAX : +66-2-541-4286

- E-mail : t_nakazawa@harmo-net.co.jp

SHENZHEN

HARMO MACHINERY (SHENZHEN) CO., LTD.

Room 8213, JinBao business building, 15 Shun Feng Road, 44 District,AnLe Community, Xin’an street, Baoan District, Shenzhen. China

- TEL : (+86) 755-88868177

- FAX : (+86) 755-83862500

- E-mail : szoffice@harmo-net.com

SHANGHAI

HARMO MACHINERY (SHANGHAI) CO., LTD.

Room 805, North Tower,Guanghua Building, 870 Maotai Road, Changning District,Shanghai

- TEL : +86-21-80199227

- FAX : +86-21-80199228

- E-mail : harmosh@harmo-net.com

Dalian Office

Room 1005, Gugeng International Hotel, No.138, Jinma Road, Dalian P.R. China 116600

- TEL : (0411)87962819

- FAX : (0411)87962819

Tianjin Office

Room 323,Yunhan Building,No.185,Qinjian Road,Hongqiao District,Tianjin 300130

- TEL : (022)87355626

- FAX : (022)87355626

Xiamen Office

Room B415, Xinxinjingdi Building, No.396, Jiahe Road, Huli District, Xiamen

- TEL : 0592-3233250

- FAX : 0592-3233250

HOCHIMINH Office

Harmo America inc.

2675 American Lane Elk Grove Village IL 60007

- TEL : +1-630-594-4116

- URL : www.harmo-america.com

SUZHOU

HARMO (SUZHOU) CO., LTD.

NO.15 XIANGPU ROAD, SHENGPU TOWN, SUZHOU INDUSTRIAL PARK, SUZHOU

- TEL : (+86) 512-6295-5112

- FAX : (+86) 512-6295-5117

- URL : www.harmo.com.cn/

Global agency

Korea

HANSE KOREA Co., Ltd.

#503,DAERUNG TECHNOTOWN 7CHA,489-11 GASAN-DONG,GEUMCI-KU,SEOUL,KOREA

- TEL: +82-2-2108-4511〜9

- FAX: +82-2-2108-4510

- URL: http://han-se.com

Philippines

NPI Machinery Inc

5th Floor Orcel II Bldg. 1611 Quezon Avenue, West Triangle, Quezon City, 1100 Philippines

- TEL: (632)926-7479

- FAX: (632)920-3096

Taiwan

XIN JU AUTOMACHINE CORP.

NO.25,Changchun 6th Rd., Zhongli Dist., Taoyuan City 320, Taiwan(R.O.C)

- TEL:886-3-4623797

- FAX:886-3-4622397

Australia

Cam-Plas Machinery Pty. Ltd.

2/30 Catherine Street, Coburg North, VICTORIA, Australia, 3058

- TEL: +61-3-9355-7099

New Zealand

TCL Hunt Limited.

7 Fisher Crescent Mount Wellington Auckland 1060 PO Box 132-166 Sylvia Park Auckland 1644 New Zealand

- TEL: +64-9-526-2700

- FAX: +64-9-525-0875

- URL: https://tclhunt.co.nz/

Brazil

Hercx Representação de Máquinas e Equipamentos Plásticos Ltda

Alameda Princesa Isabel, 654 – São Bernardo do Campo – São Paulo, CEP 09771-110, Brazil

- TEL: +55 11 2677-3040

- MOBILE: +55 11 99898-6066

- E-mail: hercules@hercx.net

Mexico

Otakara PLASTICOS

Jeronimo Trevino 3835 Col. Lopez Portillo Guadalajara, Jalisco, Mexico C.P. 44980

- TEL: +52-(33)-3663-9798

- FAX: +52-(33)-3646-2364

- URL: http://www.otakaraplasticos.com/

Israel

Multipack

3, Derech Hyam St. P.O. Box 376 81103 Yavne Israel

- TEL: +972-8942-7325

- FAX: +972-8942-0397

Italy

STAGE TECHNOLOGIES

ST.A.TE Technologies Srl Vail Vailate 15 / A、24040-Calvenzano(BG)

- TEL: 0363 8535209

- FAX: 0363 853115

- URL: http://www.state-tech.it/

Poland

HARMO REPRESENTATIVE POLAND & EAST EUROPE

ul. Kazimierza Pułaskiego 2 64-600 Oborniki

- TEL: +48-608-489-327

- E-mail: ds@darsta.pl

- URL: https://www.darsta.pl/

INDIA

KANEHIRO YANTRA PRIVATE LIMITED

Flat No 22, krishna Apartment, No.59, 1st Avenue, Ashok Nagar, Chennai – 600 083, Tamil Nadu, India.

- TEL: +91 (44) 4856-7520

- MOBILE: +91 (98) 8405-7520

- E-mail: keshavan@kanehiro.co.in

- URL: https://www.kanehiro.co.in/

ARXⅢ series (Global model)

- ARXⅢ-350/550SW・GW

-

- Overseas limited

- Large size

- 250〜600ton

- 2-plate/3-plate available

- Low ceiling type

- ARXⅢ Series

- ARXⅢ-150/250SW・GW

-

- Overseas limited

- Medium size

- 120 to 350 tons

- 2-plate/3-plate available

- Low ceiling type

- ARXⅢ Series

- ARXⅢ-80SW・GW

-

- Overseas limited

- Small size

- 40 to 70 tons

- 2-plate/3-plate available

- Low ceiling type

- ARXⅢ Series

- ARXⅢ-50/80S・G

-

- Overseas limited

- Small size

- Medium size

- 15 to 80 tons

- 2-plate/3-plate available

- ARXⅢ Series

.jpg?width=500&height=500&name=%E8%B6%85%E5%A4%A7%E5%9E%8B%E4%BB%95%E6%A7%98%7C%E3%82%A2%E3%82%A4%E3%82%B3%E3%83%B3%20(1).jpg)

%E3%83%9A%E3%83%BC%E3%82%B8%7C%E3%82%A2%E3%82%A4%E3%82%B3%E3%83%B3.jpg?width=500&height=500&name=_%E3%83%9B%E3%83%AB%E3%83%80%E3%83%BC(%E4%BD%9C%E8%A3%BD%E4%BE%8B)%E3%83%9A%E3%83%BC%E3%82%B8%7C%E3%82%A2%E3%82%A4%E3%82%B3%E3%83%B3.jpg)

.jpg?width=500&height=500&name=%E5%90%B8%E7%9D%80%E3%83%91%E3%83%83%E3%83%88%E3%81%AE%E3%82%A2%E3%82%A4%E3%82%B3%E3%83%B3%7C%E6%A0%AA%E5%BC%8F%E4%BC%9A%E7%A4%BE%E3%83%8F%E3%83%BC%E3%83%A2%20(1).jpg)

%7C%E6%A0%AA%E5%BC%8F%E4%BC%9A%E7%A4%BE%E3%83%8F%E3%83%BC%E3%83%A2.jpg?width=500&height=500&name=%E3%83%AF%E3%83%B3%E3%82%BF%E3%83%83%E3%83%81%E3%82%A2%E3%82%BF%E3%83%83%E3%83%81%E3%83%A1%E3%83%B3%E3%83%88%7C%E3%83%9B%E3%83%AB%E3%83%80%E3%83%BC%20(%E5%8F%96%E5%87%BA%E6%A9%9F%E5%81%B4)%7C%E6%A0%AA%E5%BC%8F%E4%BC%9A%E7%A4%BE%E3%83%8F%E3%83%BC%E3%83%A2.jpg)

%7C%E6%A0%AA%E5%BC%8F%E4%BC%9A%E7%A4%BE%E3%83%8F%E3%83%BC%E3%83%A2.jpg?width=500&height=500&name=HC15BPX%7C%E3%83%AC%E3%83%90%E3%83%BC%E3%83%81%E3%83%A3%E3%83%83%E3%82%AF(%E3%83%95%E3%82%A3%E3%83%B3%E3%82%AC%E3%83%BC%E3%83%84%E3%83%BC%E3%83%AB%E4%BB%98)%7C%E6%A0%AA%E5%BC%8F%E4%BC%9A%E7%A4%BE%E3%83%8F%E3%83%BC%E3%83%A2.jpg)