● Webinar report

HARMO's webinar report|Manage the whole injection molding process

We publish the contents and download document of the hold webinar on Wednesday, October 27, 2021. Please check them!

Webinar contents

Jump to selected contents by selecting the title blow.

- Introduction of Total Link system

- Don't you have any common problems in your production site?

- [Demonstration] Total Link to solve these common problems.

Webinar video

1. Introduction of Total Link system

What Total link can do is to set, activate and monitor the peripheral equipment at once. With this system, Total link contributes to solve below 5 problems of injection molding.

- Reduce setup time

- Reduce human error

- Reduce production defects

- Traceability of equipment abnormalities

- Cost reduction

2. Don't you have any common problems in your production site?

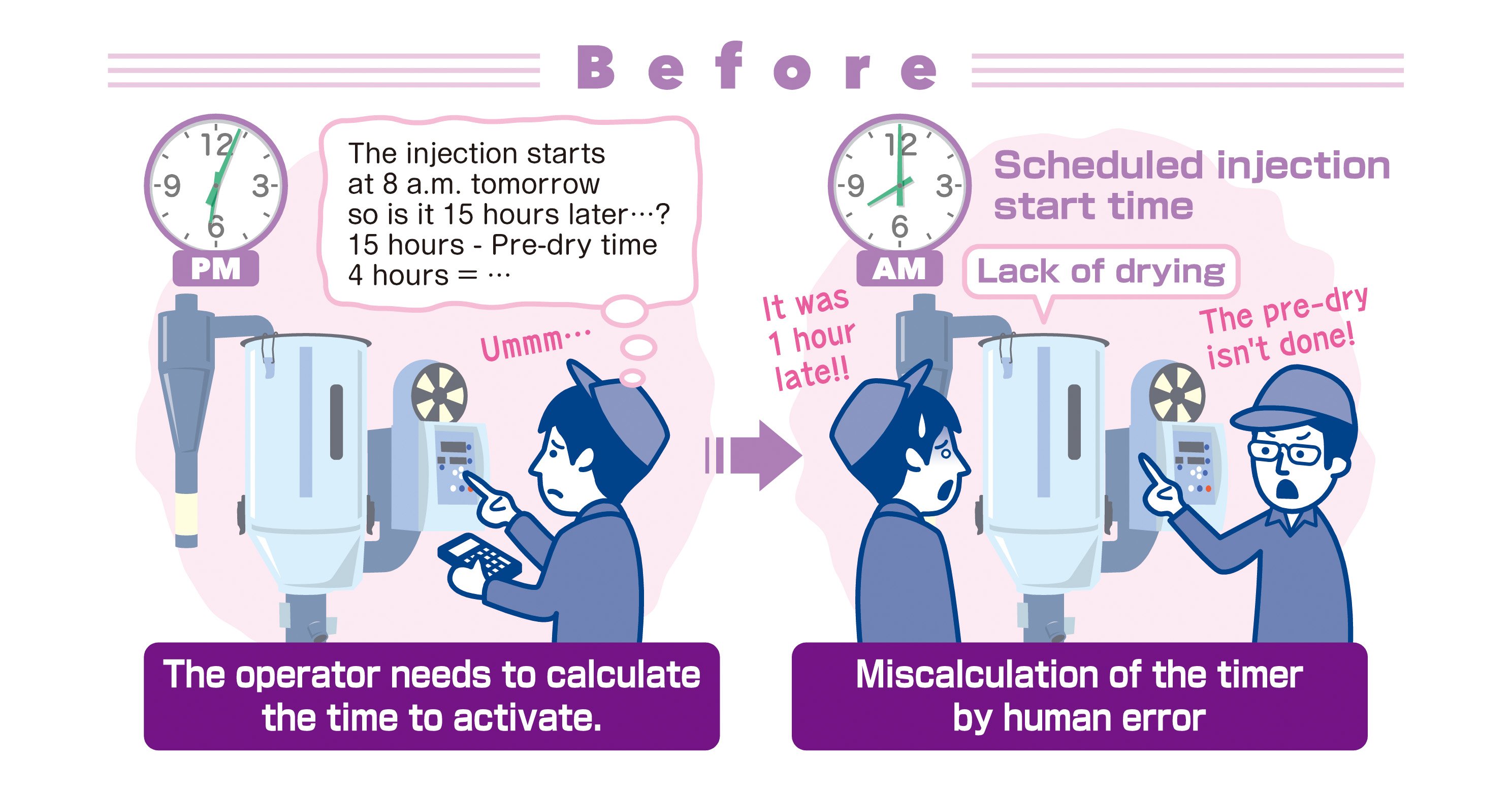

Preparation in advance

- The operator needs to calculate the time to activate

- Miscalculation of the timer by human error

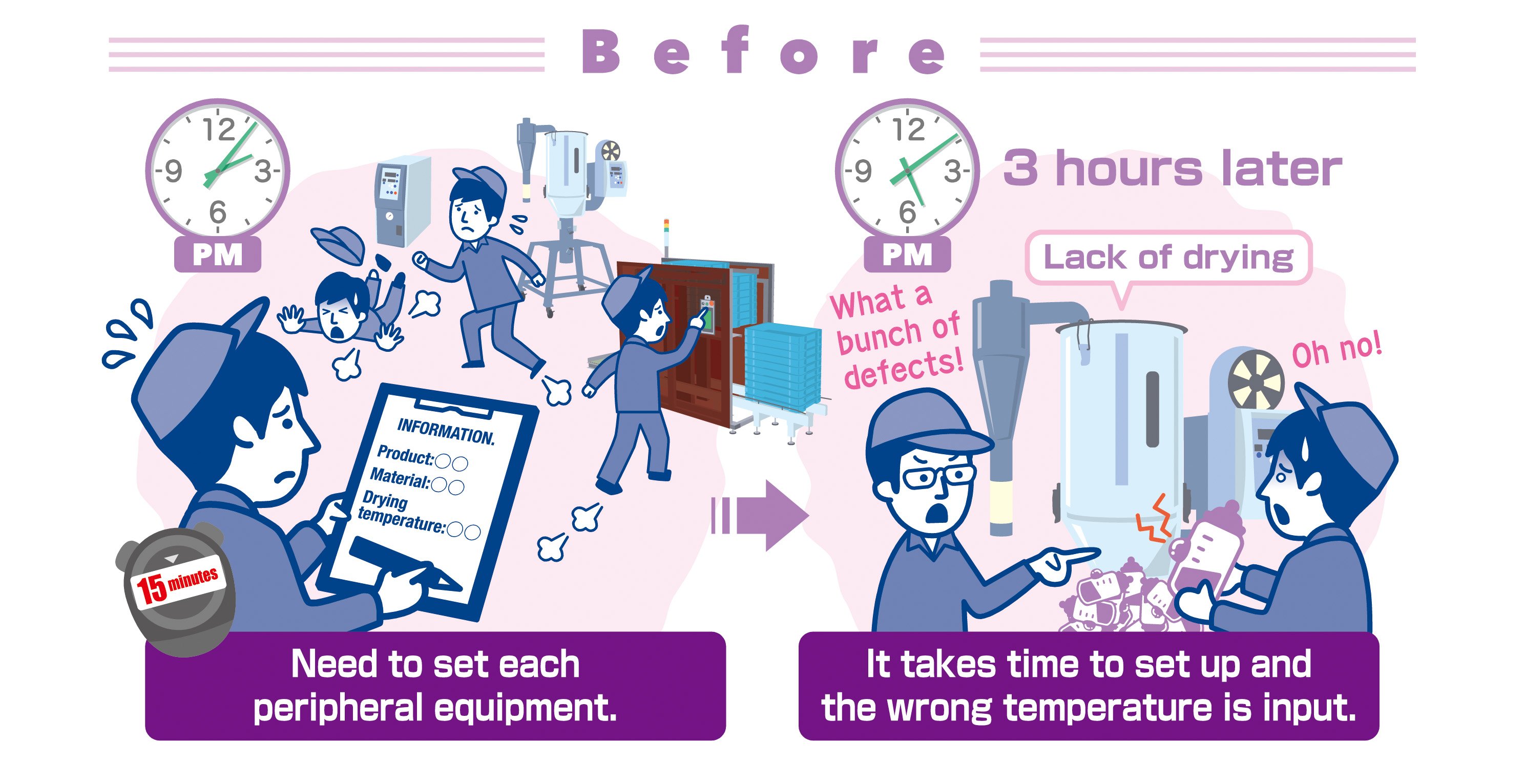

Preparation for molding

- Need to set each peripheral equipment

- It takes time to set up and the wrong temperature is input

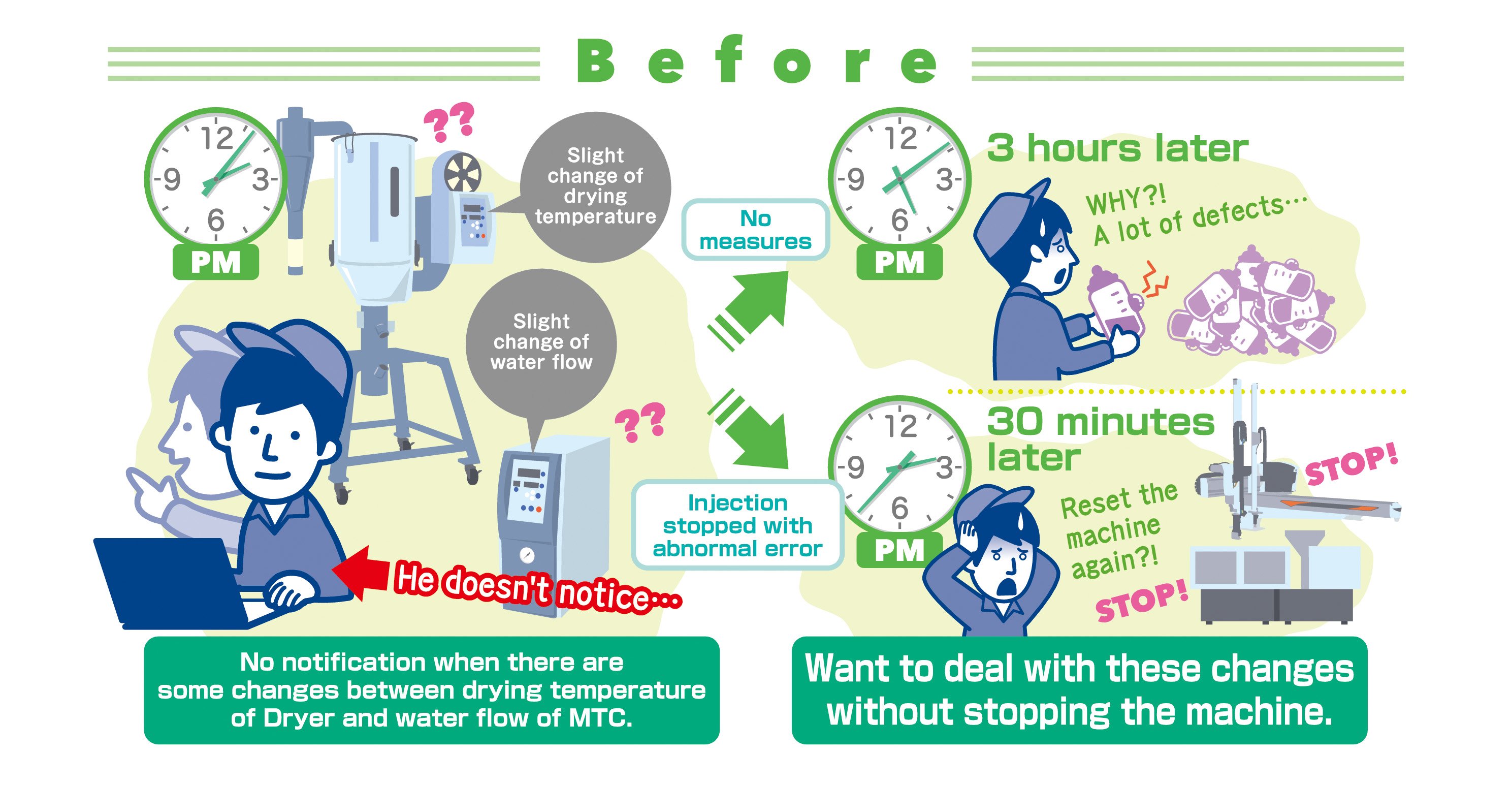

During automatic operation

- No notification when there are some changes between drying temperature of Dryer and water flow of MTC

- Want to deal with these changes without stopping the machine

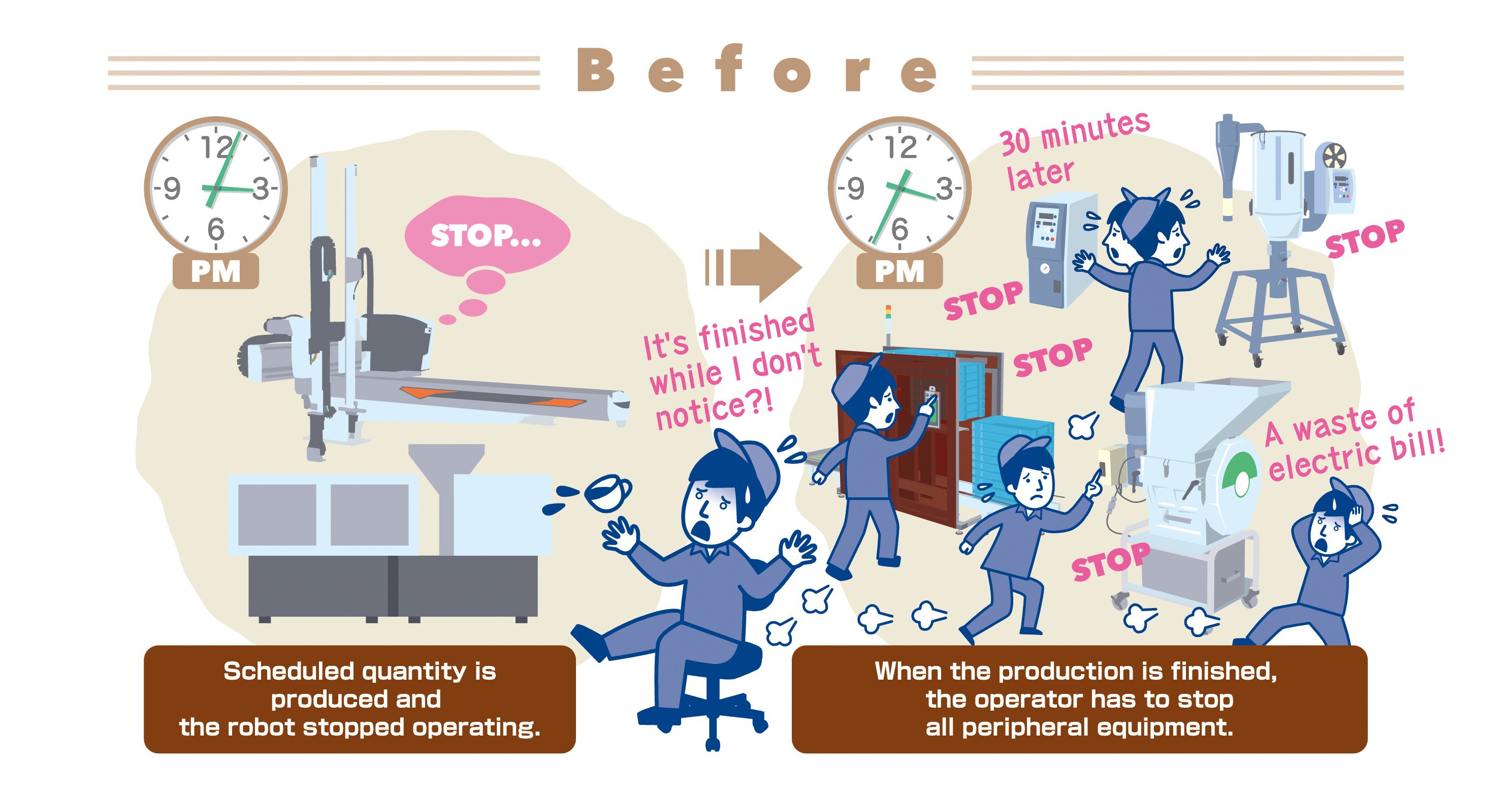

End of molding

- Scheduled quantity is produced and the robot stopped operating

- When the production is finished, the operator has to stop all peripheral equipment

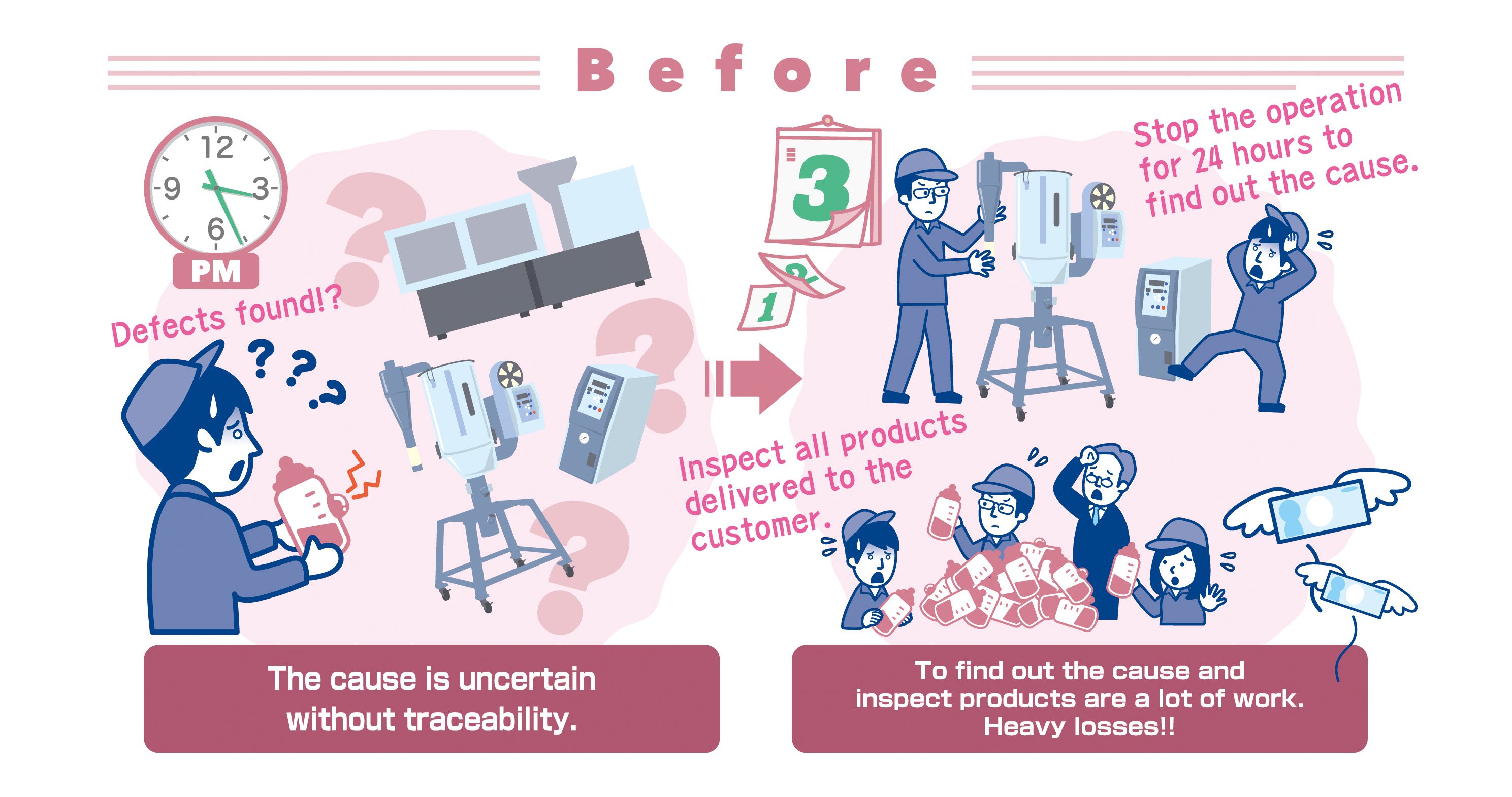

Traceability

- The cause is uncertain without traceability

- To find out the cause and inspect products are a lot of work. Heavy losses!!

3. [Demonstration]Total Link to solve these common problems

Preparation for molding

Total Link system can remember the value and change it automatically

Remember set value of peripheral equipment with mold memory of the robot. Automatically change to corresponding set value and display the setting of peripheral equipment on the pendant when mold changing.

During automatic operation

Total Link system can monitor the whole process

By monitoring the temperature, water flow, abnormality, power brake and stop of peripheral equipment, the robot separates the products that are needed to be inspected.

End of molding

Equipments will stop automatically

When auto operation has stopped, the robot instructs peripheral equipment to stop the operation.

Contact us if you have problems of automation, quality improvement and cost reduction.

Before we introduce our products, we would like to hear your current situation and concerns such as automation and productivity improvement. Once we receive a contact, we will get back to you and figure out the best way for you.

Please download a document for your reference.

Recommended for

- Want to notice small changes in equipment

- The quality is affected depending on workers skill

- Having problems of human errors

Related articles of automation, quality improvement and productivity improvement.

- No need for stroke adjustment (take-out robot)

- From pneumatic swing robot to servo driven swing robot

- If you're having trouble with Corona, why not use a stroker to make it unattended?

- [Must see] For business owners: Fixed cost reduction

- [Must see 2] For managers: Toward zero defective products

- Dramatically improves the molding defect rate due to insufficient drying

- We'll solve it! Your dehumidifier dryer problems

%20(1).png)

.jpg)