● Webinar report

HARMO's webinar report|Total Link "Manage the whole injection molding process"

We publish the contents and download document of the hold webinar on Thursday, January 27, 2022. Please check them!

Webinar contents

Jump to selected contents by selecting the title blow.

- Introduction of Total Link

- [Demonstration] Preparation in advance "the robot sets the timer automatically"

- [Demonstration] Preparation for molding "to prevent an insertion error of the hoses of MTC"

- [Demonstration] End of molding "cool the mold and make air purge automatically"

1. Introduction of Total Link

What Total link can do is to set, activate and monitor the peripheral equipment at once. We introduced 3 other functions adding to the last webinar under the theme of deep dive into Total Link "Manage the whole injection molding process."

- Preparation in advance "the robot sets the timer automatically"

- Preparation for molding "to prevent an insertion error of the hoses of MTC"

- End of molding "cool the mold and make air purge automatically"

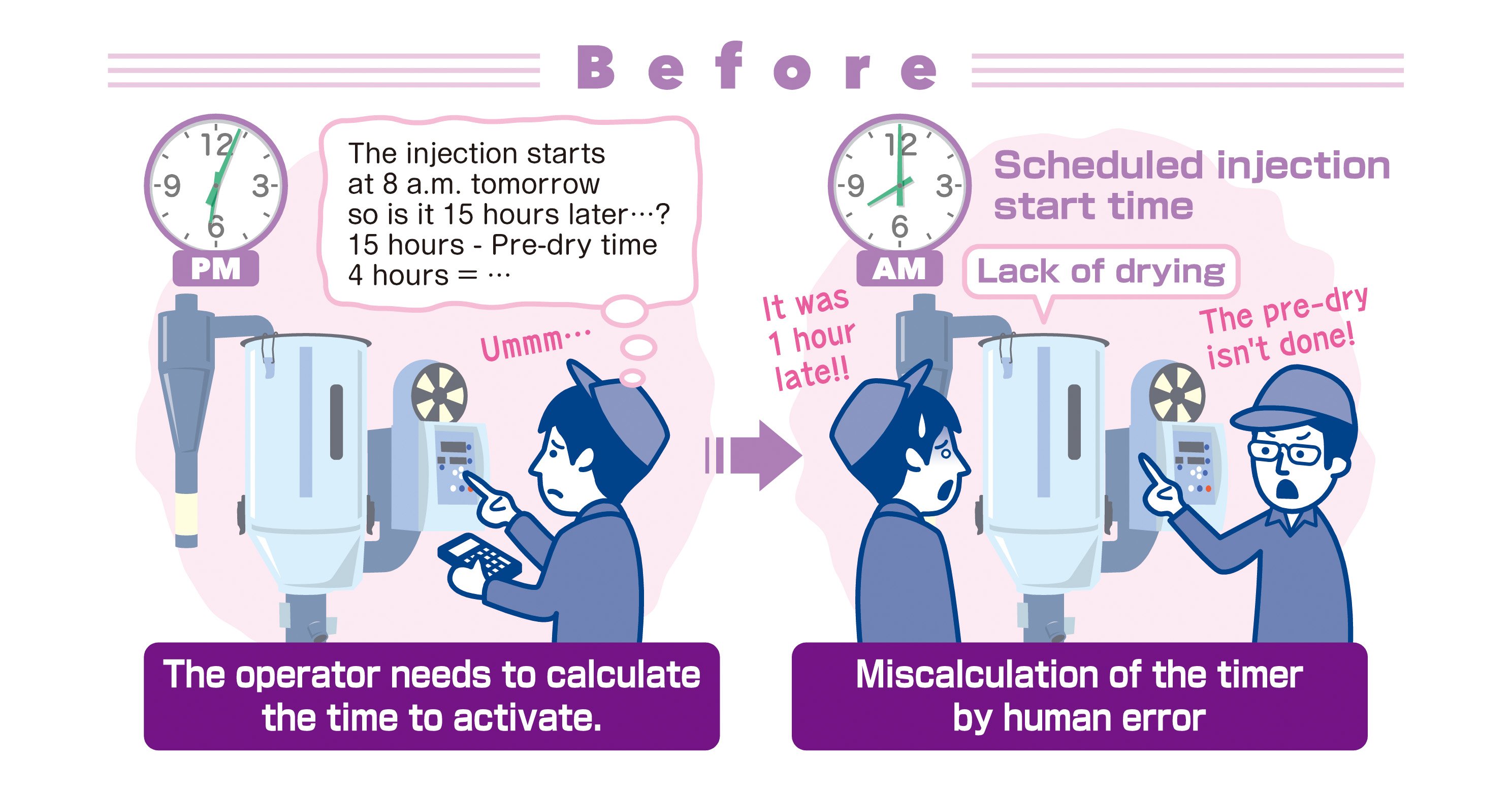

2. Preparation in advance "the robot sets the timer automatically"

- The operator needs to calculate the time to activate

- Miscalculation of the timer by human error

With Total Link, the operator can avoid miscalculation and also reduce the time for setting each equipment.

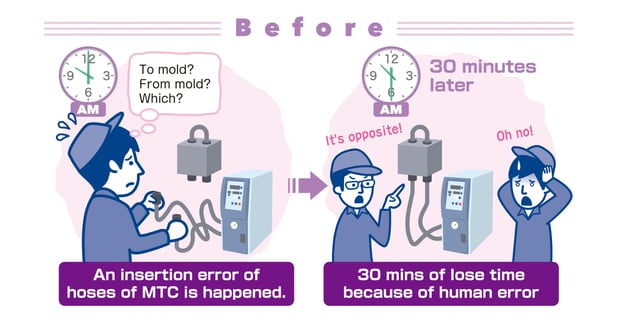

3. Preparation for molding "To prevent an insertion error of the hoses of MTC"

- Cannot notice the wrong plumbing and produce production defects

With Total Link, you can quickly notice the mistake of plumbing and fix it and get back to the correct production.

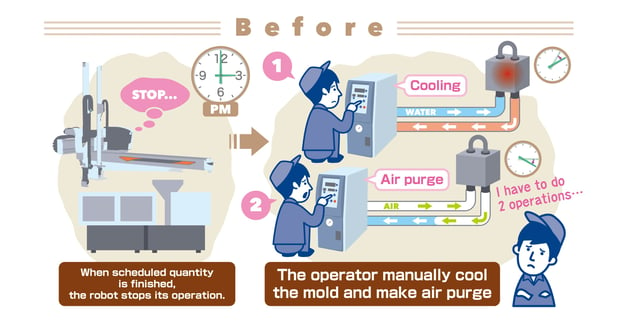

4. End of molding "cool the mold and make air purge automatically"

- 2 different operations are needed for MTC at the end of molding.

With Total Link, the robot sends the signal to cool the mold and do air purge automatically to the MTC. The operator can use the time for other things.

Contact us if you have problems of automation, quality improvement and cost reduction.

Before we introduce our products, we would like to hear your current situation and concerns such as automation and productivity improvement. Once we receive a contact, we will get back to you and figure out the best way for you.

%20(1).png)

.jpg)