Do you have any problems using recycled materials in your daily life?

Many of our customers told us that they have a lot of problems such as,

- Too much powder

- Too many missed cuts

- Can't keep the automatic operation, etc.

Harmo's SPC can realize stable cutting and solve all these problems! Grinding materials with a lot of powder can cause weighing errors and white and black spots.

In addition, many misscuts can cause bridging in the hoses during material transport, which can interfere with automatic operation and lead to unstable molding conditions, resulting in defective molding.

In today's resin shortage, we cannot afford to waste materials!

"I want to reduce the loss in material cost!"

"I want to achieve zero defective products by recycling molding!"

"I want to achieve stable molding!"

That's what Harmo's SPC machine is all about!

Differences between SPC and other granulators

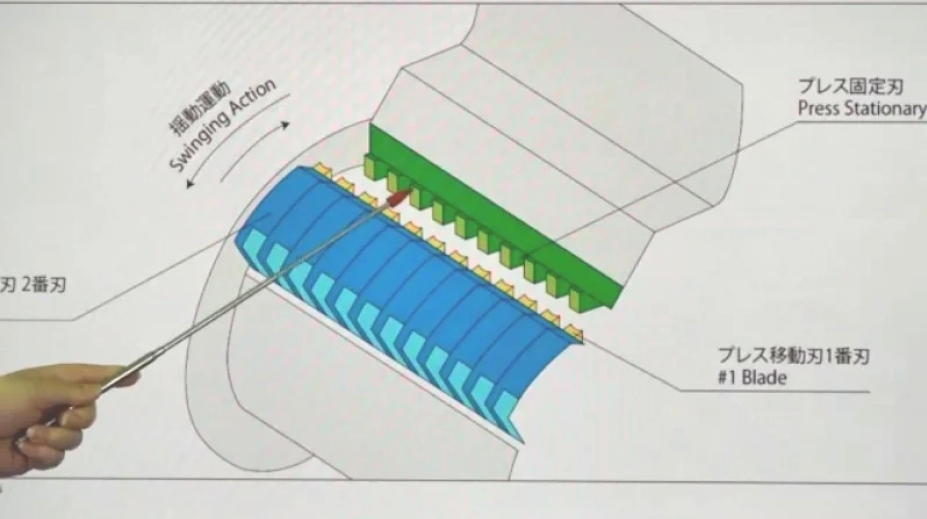

The main difference between SPC and other companies' granulators is cutting method.

Most of the crushers in the world use the "screen cut method", but SPC uses Harmo's original "swing press cut method" to continuously press cut resin into a certain size.

The size of blade of swing press cut is set close to size of virgin pellets (2.1mm x 3.5mm and 2.8mm x 4.5mm), which makes it possible to achieve a stable size cut.

Once material has been cut by press-cut blade, it is structurally impossible to press-cut it again, thus reducing generation of powder, static electricity, and heat.

Sample cut request

Harmo is also a powerful tool for cutting soft materials!

We have a special machine for soft materials (SPCⅢ-S series), so if you have soft materials that have been difficult to cut, please try a test cut!

Expected effect

If you can achieve a uniform grain cut, you can reduce number of defective products in recycling molding, stabilize molding conditions, and increase recycling ratio. Please try our SPC!