Services

Don't you have any following problems with recycled material?

✔️ Recycled material crushed by a crusher isn't uniformed so it is hard to use them in real production.

✔️ Using recycled material containing powder/dust, appearance defects such as white spots can happen.

✔️ Considering the quality of the products, we give up recycling expensive material.

✔️ It takes time to measure the material because the size of recycled material isn't even.

Harmo's Gran cutter can help you to solve

these problems.

What is important to improve recycling rate is "Gran Cutter" not "Crusher".

4 advantages of Gran Cutter

Cost reduction by increasing recycling rate

and productivity

A few dust from

recycled material

Prevent

appearance

defects

By equalizing the size of

recycled material

Productivity

improvement

With uniform size

recycled material

Shorten

measuring time

***

Motion

Example

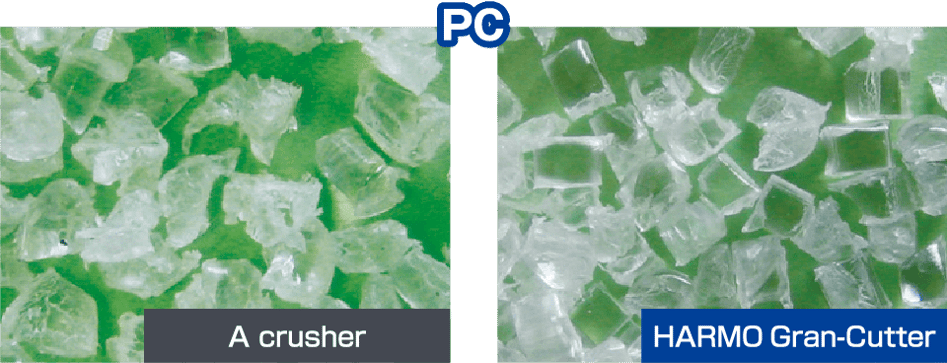

Cut example

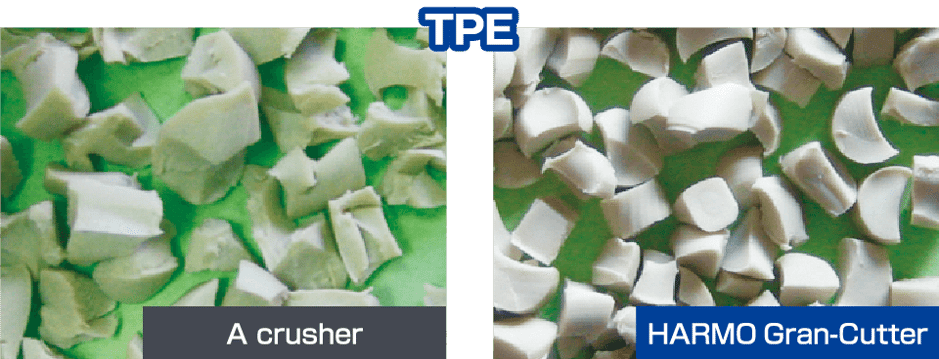

A crusher: cracked and not uniformed shape

Gran-Cutter: maintaining the transparency and uniformed shape

A crusher: the materials are torn apart and uneven in size

Gran-Cutter: 90% of cut materials are in the target size (2.8m/m to 4m/m) and almost-equally sized

Advantages

Cost advantage

Recycling rate

0% → 10%

A camera manufacture

Molding lenses with high-quality materials ($30/kg)The customer used only virgin material but by installing Gran cutter, recycling rate is increased 10% from 0%.

Annual cost saving:

1.8 million USD.

An automotive parts manufacture

Improving recycling rate is a big task because of multiple types production in large quantities. Installing Gran cutter, recycling rate is improved and realized annual cost reduction of 1.8 million USD.Mixing rate of recycled materials; 20%

A glasses manufacturer

The customer is using elastomer. The quality of products when using recycled material cut by a crusher wasn't stable. However by installing Gran cutterm the quality of recycled material was improved and also mixing rate was improve. It lead to cost reduction.HARMO Co.,Ltd.

About us,

we are a comprehensive manufacturer of molded product removal robots

recognized by the world.

We grasp the high-level and wide-ranging needs of the world standard and build trust with our customers through perfect after-sales service.

Company Name

HARMO Co., Ltd.

Business Activities

Development, manufacture and sales of industrial robots(automated pick-up equipments for injection molded parts) and streamlined auxiliary machines for plastic molding machine

International Marketing Department

4124-1 Minamiminowa-mura Kamiina-gun Nagano, 399-4595

+81-265-73-8820

Sales Office (Subsidiary)

Singapore, Philippines, Malaysia, Thailand, Vietnam, Indonesia, Shenzhen, Shanghai, America

Factory

Suzhou

Global Agency

Korea

Taiwan

XIN JU AUTOMACHINE CORP.

Email address: xin.ju-ABC-@msa.hinet.net ( Delete -ABC- and then send an email)

Australia

New Zealand

Mexico

Israel

Poland

Answering to the customer's needs with our solid support system.

As the comprehensive manufacturer of molded parts removal robot and the related peripheral machines, HARMO has been building solid structure for product development through marketing. Our wide global network not only provide us the broad field of sales, but also bring us closer to our customers through our technical support and their feedbacks.We are determined to develop, manufacture and deliver our high quality products by understanding our customers’ sophisticated yet diverse needs for automation and labor-saving system, which require high speed, preciseness, efficiency and safety.